ETI Muzzle Brake

In 2016 I designed the first draft of the ETI™ Muzzle Brake. The main objective was to move away from the generic muzzle brake designs we see in use every day. They are minimal in nature and cheap to produce resulting in a product that is lacklustre, boring and not exciting for the consumer. My approach was to focus on their inherent function and embrace that as a guide for everything else aesthetically and functionally. After rigorous testing and evaluating multiple iterations a product has come forth which merges Next-Gen aesthetics with Performance.

A design that took years to finish. A lot of customers have been extremely valuable in providing user feedback through thousands of rounds of testing. Therefore I am very excited for the Gen2. Normal muzzle brakes are often just cheap steel cilinders with holes. Not this brake.

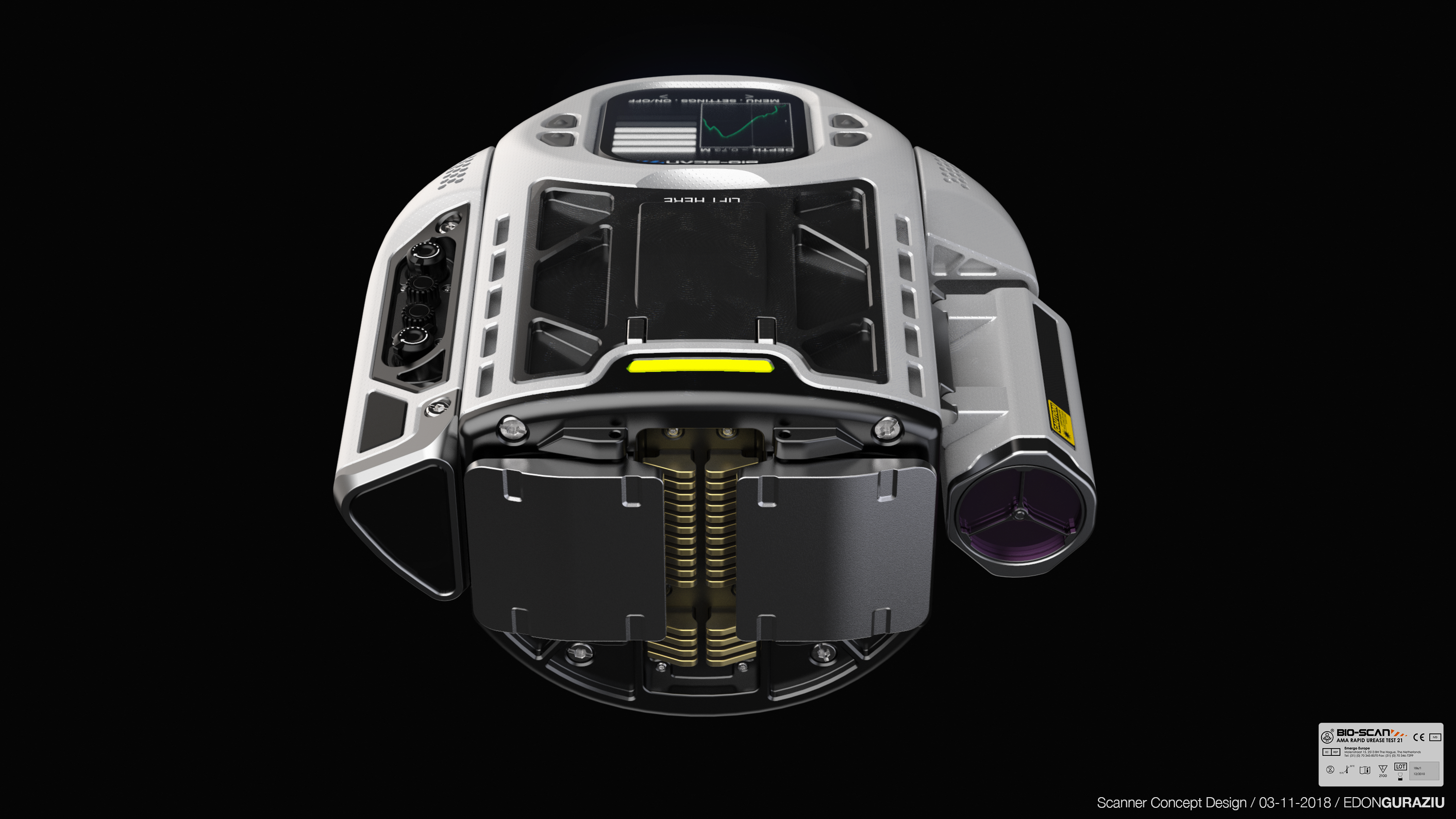

This brake has the most complex geometric body on earth. Its unique volume has been purposefully designed to accomplish perfect manipulation of the gasses exiting the muzzle. The unique L shaped ports, create high pressure areas in the smaller pockets where the flat top vents are situated for ultimate gas ejection. An inverted triangular fork has been cut from the mouth to disperse the muzzle flash in a controlled manner eliminating vertical flash projection compromising any sight picture.

Mass reduction pockets also serve to protect important product data laser etched into the steel. A flat top near the base was implemented for secure purchase with an armorers wrench to make installing easy and safe. A pilot hole has been placed on the 12 o clock position for any pin-weld applications on short barrels. The ETI™ Muzzle Brake is precisely 2.5".

This brake has the most complex geometric body on earth. Its unique volume has been purposefully designed to accomplish perfect manipulation of the gasses exiting the muzzle. The unique L shaped ports, create high pressure areas in the smaller pockets where the flat top vents are situated for ultimate gas ejection. An inverted triangular fork has been cut from the mouth to disperse the muzzle flash in a controlled manner eliminating vertical flash projection compromising any sight picture.

Mass reduction pockets also serve to protect important product data laser etched into the steel. A flat top near the base was implemented for secure purchase with an armorers wrench to make installing easy and safe. A pilot hole has been placed on the 12 o clock position for any pin-weld applications on short barrels. The ETI™ Muzzle Brake is precisely 2.5".

You can purchase the ETI™ Muzzle Brake here.

Additional Credits

Viktor Kadar - Rendering & Animation

Patrick Borgatai - Video Editing & Simulation

Yan Buyko - Sound Design